concrete batching plant

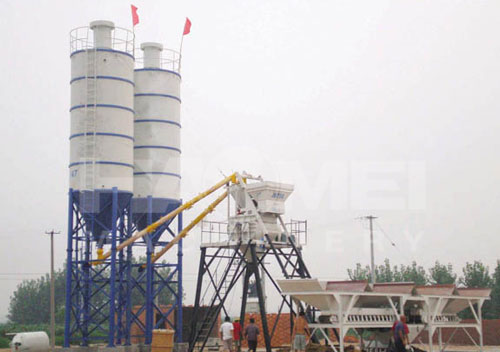

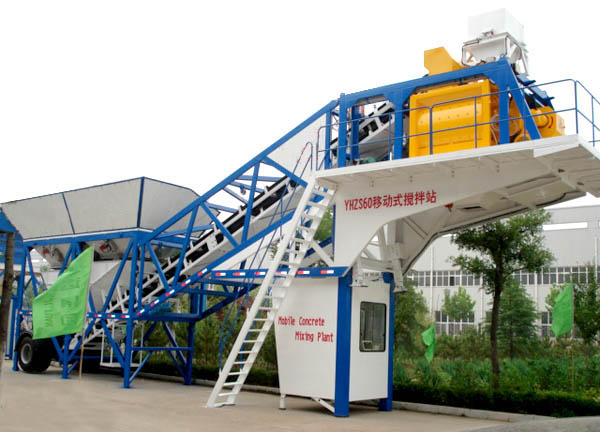

Concrete batching plant is efficient concrete equipment, which is broadly applied in large quantities and long construction period concrete production projects because of its high mechanization, automation and productivity. At present, we can provide stationary type batching plant and mobile type batching plant to our global users, and they are the main products in our company.

There are two types of concrete batching plants:

Ready mix concrete batching plants:

A ready mix oncrete batching plant combines all ingredients except for water at the concrete plant. This mixture is then discharged into a ready mix truck (also known as a concrete transport truck). Water is then added to the mix in the truck and mixed during transport to the job site

Central mix concrete batching plants:

A central mix concrete batching plants combines some or all of the above ingredients (including water) at a central location. The final product is then transported to the job site. Central mix plants differ from ready mix plants in that they offer the end user a much more consistent product, since all the ingredient mixing is done in a central location and is computer-assisted to ensure uniformity of product.

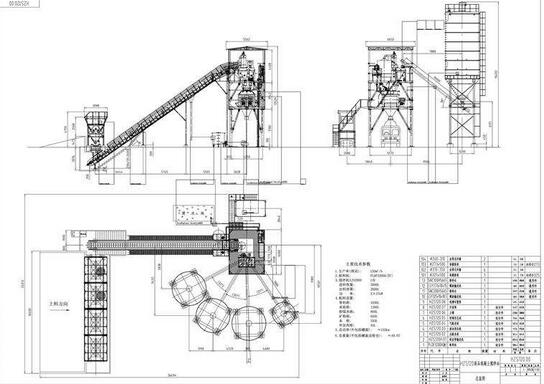

Concrete mixing plant is divided into four parts: gravel feed, powder (cement, fly ash, bulking agents, etc.) to feed, water and feed additives, transmission and storage stirred their workflow shown in Figure 1. , the mixer control system power, into the human – machine dialogue operation interface, system initialization process, including recipe number, grade concrete slump, producers, etc. according to the amount of weight carried on each silo, weighing hoppers. detection, output material or material empty full signal, prompting the operator to determine whether to activate the control program starts stirring sand, stone belt motor fed into the metering hopper; open fly ash, cement tank valve, start the electromechanical screw conveyor ash cement to the metering hopper; open water reservoir and control valves admixture pool water and additives into the metering hopper metered meet the set requirements doo door open metering, mixing the ingredients into the mixer within already started to set. time to open the mixer door, into the concrete mixer had received material.

The Introduction of concrete batching plant Components:

concrete batching plant layout

1). Aggregate Batching Machine

1.1. Adopt combined structure and modular unit, convenient to install and remove.

1.2. Mixing and aggregate lifting system adopt double shaft compulsory concrete mixer.

1.3. Aggregate batching system adopts PLD concrete batcher which offers efficient and accurate measurement.

1.4. Powder-lot is electronic measured and highly accurate dosing.

1.5. Water is flow-metering, simple and practical, highly accurate dosing.

2. PLD Batching Machine

2.1. The series of concrete batching plant adopts electronic weighing digital display.2.2. It has features if accurate weighing, high batching accuracy, fast speed, strong controlling ability, simple operation, reasonable design and compact structure and long service life.

3).Concrete Mixer

3.1. concrete mixer has the advantages of reasonable design, compact structure and convenient operation. Stable working and good mixing performance and low energy consumption, low noise and long life wearing parts.

3.2. Mixing system: motor, belt pulley, gear, mixing drum.

3.3. Feeding system: Lifting motor, feeding frame, hopper, feeding mouth.